Manufacturing & quality

Maintaining the highest standards of safety and performance

State-of-the-art facilities

Vestergaard’s manufacturing and quality systems are designed to ensure consistent, life-saving performance for public health products used in high-risk environments worldwide. Our manufacturing facilities are based in Vietnam, with state-of the-art processes informed by close collaboration with technical experts, including researchers, and implementation partners. Our facilities are independently audited and meet certifications including SA8000:2014 and ISO 45001:2018.

From raw materials to final delivery, we prioritize:

Quality, precision and consistency

Safe and ethical production

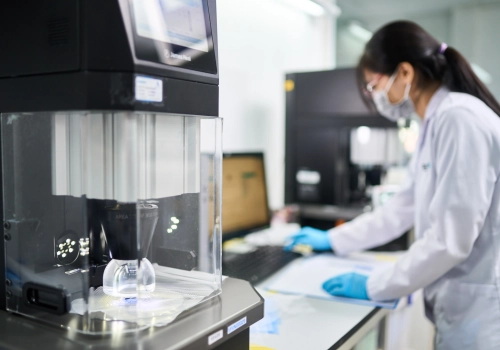

Our Vestergaard quality control lab

With over 30 quality checks from manufacturing to packaging, we can detect and resolve issues early. When lives are at stake, there’s no room for compromise.

At our ISO/IEC 17025-accredited quality control lab in Vietnam, products like PermaNet® Dual undergo five times more testing than comparable alternatives. Testing includes insecticide concentration, bioefficacy, and packaging integrity, with results validated by both in-house and external laboratories.

We follow ISO 2859 and ISO 3951 protocols to ensure sampling and testing meet international quality benchmarks. Continuous performance monitoring and structured feedback loops help us maintain trust with our customers and ensure product consistency.

After distribution, we track how our products perform over time, helping us refine our approach and respond to customer feedback, including through field studies led by the Vestergaard–Noguchi Vector Labs in Ghana, and partner consultations.